The different types of briquette machines available in the market and their features

There are lots of types of briquette machines with different working principles. Each machine works on different pressures and is suitable for different materials. Thus How do they work differently? What are their advantages & disadvantages? Let’s go through this article.

A briquette machine is used to convert the waste powder into a regular shape block that can help to improve the conditions for those powder, making them simple for transportation, storage, and more useful for further usage. The briquette system is able to deal with entire types of materials under suitable sizes and moisture.

Briquetting work always takes place with the binder as the raw particles require the binding effect to get enough strength when they are turned to briquette. Biomass and industrial waste are occasionally different from each other when briquetting because of the binder source they are using.

Different Types of Briquette Machines Available in the market

Screw type

The screw type briquette machine utilizes the auger to press the raw material, with different materials, it can be equipped with or without the heating system.

As the screw briquette machine works with a pressure not that high, binders are always required forming the briquette. Equipped with a heating system will help the biomass material melt the internal lignin and turn it to a high-performance binder. Apart from it, other materials also work with this briquetter like charcoal, coal, etc. These materials must be well mixed with the binder to get the briquette forms.

Features of screen type briquette Machine

- Shaping drum, special casting steel, inner barrel boron treatment, constantly used for more than 5 months.

- Accessories, our large factory of welding rod joint development makes this special mechanism of carbon electrode welding procedure easy and with high quality, hardness up to more than 75 degrees, and solves the crack resistance, you don’t need to preheat and weld directly.

- Screw Shaft, advanced design, high speed of producing rod, high density, high resistance to wear, one welding time can work constantly for over 30 hours.

Hydraulic type

The hydraulic type works with a hydraulic pump station that supplies a very big pressure. Due to its high pressure, nearly all the materials can be briquetted with this system.

Metal, as a raw material which reflects plasticity under high pressure, is specially appropriate to be briquette by the hydraulic type briquette machine.

Features of Hydraulic type briquette Machine

- Besides, the hydraulic system is equipped with a cooling device to decrease high processing temperature.

- The pressure value can be changed by handling the overflow valve. Thus the compression ratio will match with the forming density of briquettes to deal with different kinds of raw material.

- The quality as well as performance of the hydraulic briquette machine can meet EU standards.

Piston type

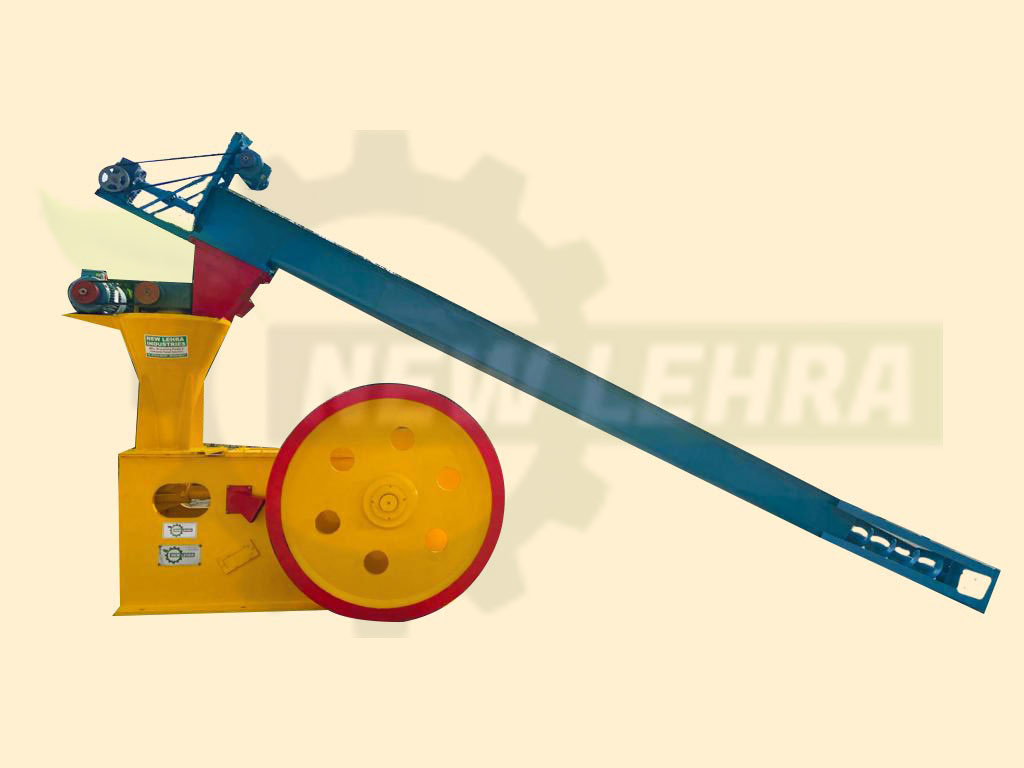

The piston type utilizes the rotary power of the mechanical device or the thrust of the hydraulic cylinder to reciprocate the piston (or the plunger), and the piston (or plunger) drives the ram to reciprocate in the forming sleeve to generate a pressing force to form the material to briquette.

Features of Piston Type Briquettes Machine

- High output

- Low electricity consumption

- Less limited on raw material size

Roller Type

Roller press functions with two close rotating rollers at the same speed but with opposite direction. The two rollers, with the similar width and diameter, have holes on the surface. When they move, the similar two holes on the different roller will coincide at the intersection of the midline and the briquette will be pressed there.

With different pressure necessities, roller presses can be designed to several types.

A normal roller press will use a wedge iron or a spring to resolve the movable roller as it works on a low pressure. The hydraulic pump station also can be used to resolve the roller and supplies a much bigger but flexible support to the roller to work stable under high pressures.

Features of Roller Type Briquettes Machine

- High output & reliability and low energy consumption

- Relatively high working pressure, low vibration & stable operation

- Range of sizes and shapes are available

- It has the perfect effect for grinding hard & medium hard materials.

- The smart roller bearing lubrication system ensues its best performance the entire day.

- Compact steel body and affordable price makes it an ideal choice for your own use or business.

Newlehra is a professional manufacturer of Briquette machines. Get in touch with us by dialing our number or simply drop us an email.