Industrial dryers are a significant investment and one must consider it carefully before purchasing it. Technological advancements have also made drying equipment more diverse as well as complex. These changes make it challenging for non-experts to select the right machine.

Given this, this article will help buyers to make the correct purchasing decision by highlighting the key factors to consider before making a selection, as well as a few of the most popular machines available on the market currently.

The worldwide market for industrial dryers

Value of the industrial dryers market was $4 billion in 2015 and is estimated to grow at a compound annual growth rate (CAGR) of 4.3%, reaching $6.37 billion by 2026. Various factors are fuelling this growth, comprising increasing demand for these machines from several end-use industries such as pharmaceutical, food, fertilizers, chemicals, minerals, cement, and paper & pulp. The industrial dryers’ ability to efficiently process huge quantities of materials, thus helping industries to meet their drying aims, makes it an invaluable asset to several industries. And as a result the application of dryers in several sectors will continue to grow.

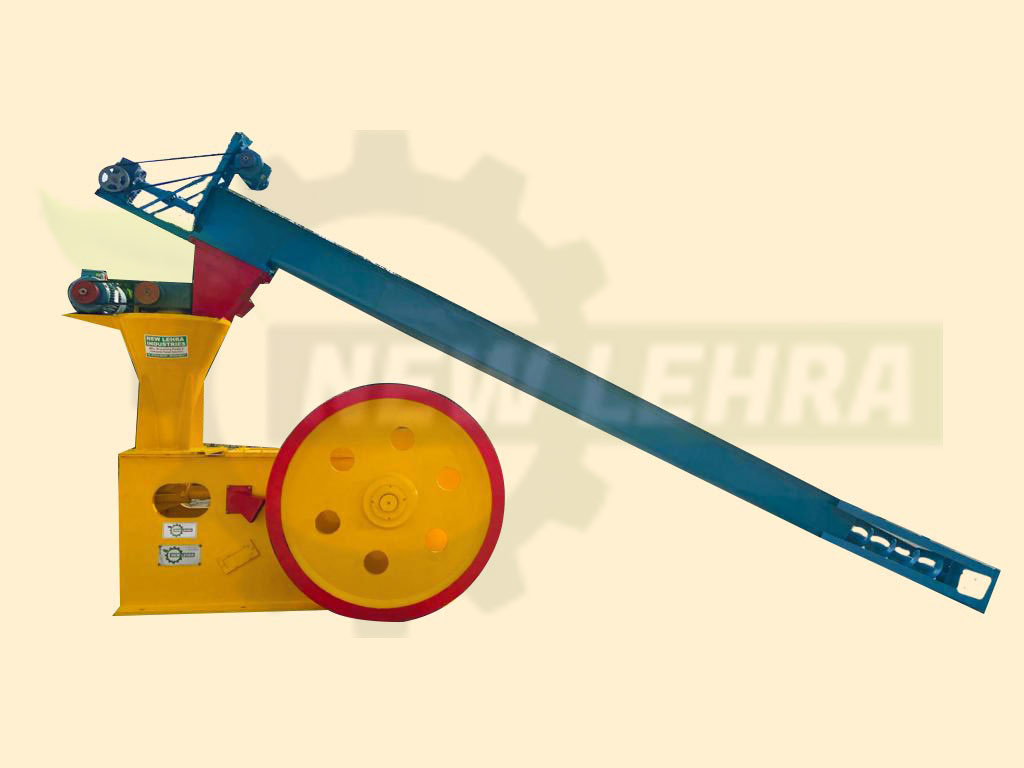

Rotary Drum Dryers are industrial drying equipment often used with bulk solids to reduce their moisture content by coming in contact with the heated gas. The rotary dryer enables the feed material to directly interact with the hot air to flush out the moisture. Although, the indirect rotary dryer has the hot air separated from the feed material by a tube or metal plate. It is thus appropriate for heat-sensitive materials. It can also perform both batch and constant drying processes.

Tips For Choosing Right Rotary Drum Dryers For Your Drying Needs

One of the most significant steps in selecting the ideal dryer is to test wet materials on the drying equipment, guaranteeing that the final product is dry and is of the desired quality. However, before testing starts, here are six factors to consider when narrowing down on the drying system.

1. Size and density

The size and density of materials to be dried decide the size and capacity of the drying machine to be bought. For example, smaller materials need different drying methods to larger ones. And as with size, the density of the material is also a key importance. The density decides the movement of the material through the dryer, with denser material needing different machines from the less dense ones.

2. Moisture content to be dried

It is also significant to know the material’s moisture content at both the beginning and the end of the drying process. Testing the dryer in advance can help to decide the dryer’s efficiency and whether it is the correct size. If the company detects variation from their end product moisture content goal, they must consider different dryer sizes.

It is also significant to decide how the material to be dried is holding the moisture. For example, a vaporizing machine will be sufficient if the moisture is only on the surface. Although, if the material has absorbed the moisture content, a machine which thoroughly dries from the inside is required. This factor also helps establish whether to add pre-dying necessities to the processing line.

3. Material handling

How the wet material is handled also plays a role when selecting a dryer. Sticky or sludgy materials are often forced into the dryer to keep them away from plugging the line. If the company handles sticky materials, the engineer could select drying machines with non-stick surfaces or built-in paddles to keep the materials flowing.

The material’s abrasiveness as well as fragility are other factors to consider. If the company intends to dry fragile material, it must avoid drying equipment which roughly moves materials, and may opt for a machine which uses a gentler method. Alternatively, if the dried materials are abrasive, the company could select abrasive resistant drying machines to prevent maintenance issues or damage.

4. Reaction to heat

Few materials are affected by heat and could react when they reach certain temperatures. If the machine is drying a chemical solution then it could result in a chemical reaction.

Also, certain heat sources could melt or burn some materials if they are exposed to certain temperatures for a long time period. Thus, the drying machine could be slower or larger to help lower the temperature. If the company deals in materials likely to melt, it could select a dryer with a high temperature but short residence to prevent a possible product reaction.

5. Efficiency & price

Price consideration forms part of the entire major purchase. The company will consider the upfront capital cost when purchasing the machine and the operational costs during the machine’s lifetime. However, the upfront cost must not be the only determinant of the dryer’s cost-effectiveness because few machines may cost less upfront but operate inefficiently, thus costing more in the long run. And it is also necessary to consider the type of fuel running the machine.

6. Production necessities

Ultimately, the dryer’s size must match the expected production levels. It’s worth considering whether the dryer will run constantly or operate in batches. If the company has large jobs which need a high output, using an undersized dryer will lead to clogging, and the operation could stop because it will overwhelm the machine. On top of this, the dryer could even burn out quicker than expected. Alternatively, if an oversized dryer is chosen, it will waste energy. It could also damage or over-dry the product.

Conclusion

Industrial dryers can be an invaluable asset to many businesses and have several useful applications which will see a growing demand over the coming years. This article has thus outlined a few key points to consider when selecting the right drum dryer for your drying needs. Don’t forget to visit our home page at http://newlehra.com/.