Briquette Cum Pellet Machine

Briquette cum Pellet Machine is used to make Briquette and Pellets out of any agricultural and forest waste. Briquettes and Pellets are used in the replacement of fossil fuels which intern proves to be an environmental friendly product. This a Binder less technology. No adhesive or binder is used while producing Briquettes from our machines.

Raw materials: Raw materials which can be used to make Briquettes:

Agricultural waste: Rice husk, Mustard husk, Paddy straw, Groundnut shells, Cotton stalks, Sugarcane leaves and trash, Coconut shells, Arhar stalks, Coir pith, Coir dust, Bamboo sticks, Bamboo dust, Coffee waste, Corn cobs waste, Coffee waste etc.

Forest waste: Saw dust, Wood chips, Tree branches, Wood shavings, Tree twigs, Veneer waste, Pine needles etc.

Other waste: Press Mud, MSW, Paper waste, Bagasse.

*Input raw material has to be granulated form with the moisture content between 8-12%

Briquette size: 70mm/90mm/100mm

Pellet Size: 8mm/10mm/12mm/20mm

FAQs

A briquette cum pellet machine is a type of machine that can produce both briquettes and pellets from various types of biomass or waste materials. This machine combines the advantages of both briquetting and pelleting, providing more flexibility and versatility in the production process.

Briquettes and pellets have similar uses as a source of fuel for heating and cooking, and can be made from materials such as wood chips, sawdust, agricultural waste, and other biomass materials. However, there are some differences between the two. Briquettes are typically larger and have a more uniform shape, while pellets are smaller and more compact.

The briquette cum pellet machine is designed to produce both types of fuel by using a combination of compression and extrusion. The material is fed into the machine, where it is compressed into briquettes or pellets depending on the type of die used. The machine can also be adjusted to produce briquettes or pellets of different sizes and shapes.

Overall, the briquette cum pellet machine is a versatile and efficient tool for producing biomass fuels, and can be used in various industries such as agriculture, forestry, and manufacturing. It provides a sustainable and eco-friendly alternative to traditional fuels, while also helping to reduce waste and save on costs.

There are several benefits of using a briquette cum pellet machine for producing biomass fuels, including:

Versatility: The machine can produce both briquettes and pellets from a variety of biomass or waste materials, providing more flexibility in the production process.

Efficiency: The machine uses compression and extrusion to produce briquettes and pellets, which results in high-density and uniform products. This makes them more efficient to transport and store.

Eco-friendly: Briquettes and pellets produced from biomass materials are renewable and carbon-neutral, making them a more sustainable and eco-friendly alternative to traditional fossil fuels.

Cost-effective: Using waste materials such as sawdust, agricultural waste, or forestry residues to produce briquettes and pellets is a cost-effective way to reduce waste and save on raw material costs.

Easy to use: Briquette cum pellet machines are easy to operate and can be adjusted to produce briquettes or pellets of various sizes and shapes.

Reduced emissions: Burning briquettes and pellets produces lower emissions than traditional fuels such as coal, which makes them a more environmentally friendly option.

Overall, using a briquette cum pellet machine provides several benefits for both the environment and the economy. It helps to reduce waste and save on costs, while also providing a sustainable and eco-friendly alternative to traditional fossil fuels.

A briquette cum pellet machine from New Lehra processes biomass into solid fuel in both briquette and pellet form. It allows flexible fuel production based on market demand. The machine supports multiple biomass applications.

The machine compresses prepared biomass under high pressure through dies to form briquettes or pellets. New Lehra systems ensure uniform density and consistent output. Proper raw material preparation ensures smooth operation.

Briquettes are larger, cylindrical fuel blocks. On the other hand, pellets are smaller and granular in size. New Lehra machines cater to both formats. They’re best for different industrial needs. Pellets suit automated boilers, while briquettes suit manual feeding.

Yes, New Lehra briquette cum pellet machines are designed to produce both products with configuration adjustments. This provides operational flexibility to manufacturers. Output depends on the die and setup selection.

New Lehra machines can process sawdust and rice husk. Also, they’re capable of processing bagasse, mustard husk. Some other favourable materials are like groundnut shell and similar biomass. Raw material should be clean and properly sized. Local availability improves cost efficiency.

Yes, cow dung finds use after proper drying and processing. New Lehra machines can handle cow dung blended with other biomass. Moisture control ensures stable briquette or pellet formation.

Ideal moisture content is between 8% and 12% for efficient production. New Lehra machines perform best within this moisture range. Higher moisture may require a dryer.

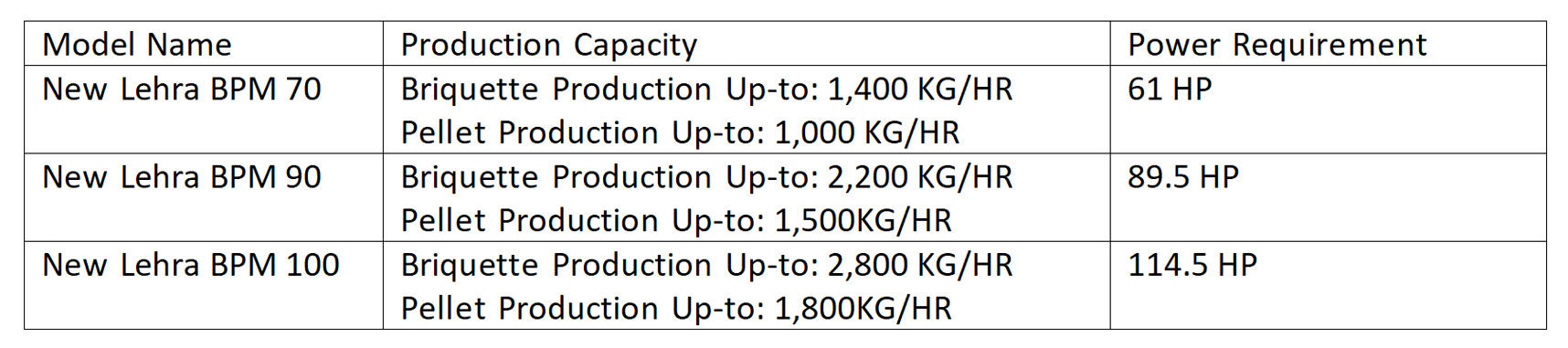

New Lehra machines are available in different capacities. Determining factors are motor size and application. Production output depends on raw material type and moisture level. It’s possible to customise Capacity as per requirement.

Power consumption varies by model and capacity. New Lehra machines ensure energy-efficient operation. Typical installations use an industrial three-phase power supply. New Lehra briquette cum pellet machines consume 7.5 kW – 30 kW. Small to mid-range units often use 7.5 kW – 15 kW. Higher-capacity industrial models may draw 20 kW – 30 kW during operation.

A dryer is essential if the raw material moisture exceeds the recommended limits. New Lehra offers integrated solutions with dryers when needed. Proper drying improves output quality and machine life.

There are several types of briquette cum pellet machines available in the market. Here are some of the common types:

Flat die pellet mill: This type of machine is designed to produce small scale pellets from biomass materials. It uses a flat die to compress and extrude the material to form pellets.

Ring die pellet mill: This is a more powerful and efficient machine that is capable of producing larger quantities of pellets. It uses a ring die and rollers to compress the material and form pellets.

Screw extruder briquette machine: This type of machine is designed to produce briquettes from biomass materials. It uses a screw extruder to compress the material and form briquettes of various shapes and sizes.

Piston press briquette machine: This is another type of machine that is used to produce briquettes from biomass materials. It uses a piston and a die to compress the material and form briquettes of various shapes and sizes.

Hydraulic press briquette machine: This is a more powerful and efficient machine that is used to produce high-density briquettes from biomass materials. It uses a hydraulic system to compress the material and form briquettes of various shapes and sizes.

Overall, the type of briquette cum pellet machine to use depends on the specific needs and requirements of the user, such as the scale of production, the type of biomass materials, and the desired output.

A briquette cum pellet machine is a type of machine that combines the benefits of both briquetting and pelleting. It is used to produce both briquettes and pellets from various types of biomass or agricultural waste materials. The machine uses compression and extrusion to form either briquettes or pellets of various shapes, sizes, and densities, depending on the material being used and the desired output. Briquettes and pellets produced from biomass materials are renewable and carbon-neutral, making them a sustainable and eco-friendly alternative to traditional fossil fuels. Overall, the briquette cum pellet machine provides several benefits for both the environment and the economy, including cost-effectiveness, efficiency, and reduced emissions.

New Lehra briquette cum pellet machine prices depend on capacity and configuration. Entry-level machines start from several lakhs. Higher-capacity systems cost more. Final pricing is based on customisation. New Lehra briquette cum pellet machines are available in the ₹6,50,000 – ₹18,00,000 range. Smaller entry-level units, the ones that offer 500 – 800 kg/hr, are available in the range of ₹6,50,000 – ₹9,50,000. mid-range units cost around ₹10,00,000 – ₹13,50,000. Again, larger industrial setups are available for ₹14,00,000 – ₹18,00,000+.

Plant setup cost depends on machine capacity and dryer inclusion. Also, another essential factor is automation. New Lehra turnkey plants range from small-scale to industrial-level setups. Investment varies with production goals. the cost of a small-to-medium briquette and pellet manufacturing plant ranges from ₹35 lakh – ₹1.2 crore. A basic 1–2 TPH plant costs around ₹35 lakh – ₹55 lakh. Larger 3–5 TPH turnkey plants range from ₹75 lakh to ₹1.2 crore+. Final investment varies with site requirements and machinery specifications.

Yes, the business is profitable. The rising demand for renewable industrial fuels makes it profitable. New Lehra machines help convert low-cost biomass into sellable fuel. Profitability improves with scale and supply consistency.

Industries such as boilers and furnaces use briquettes and pellets. Other industries that depend on them are textile units, food processing, and power plants. New Lehra machines support fuel requirements across multiple sectors. Usage depends on combustion system type.

Pellets are better for automated boilers. Briquettes suit manual or semi-automatic systems. New Lehra machines allow manufacturers to serve both markets. Fuel choice depends on boiler design.

Biomass briquettes and pellets offer good calorific value. Raw material plays a major role here. New Lehra machines ensure dense fuel with efficient combustion. Biomass type is a determining factor for the actual value. With New Lehra biomass briquettes, you can expect a calorific value of around 3,500 – 4,500 kcal/kg. Biomass pellets generally range between 4,000 and 4,800 kcal/kg. Higher density is what impacts the price.

Space requirement depends on machine size and raw material storage. Also, dryer integration plays its role here. New Lehra provides layout guidance for efficient installation. it’s recommended to pay attention to Adequate ventilation and movement space.

For proper maintenance you need to consider Regular lubrication and die inspection. Also, consider cleaning regularly. New Lehra machines are built for easy maintenance and long-term operation. Scheduled servicing ensures consistent performance.

With proper maintenance, New Lehra machines guarantee long operational lifespan. Heavy-duty construction ensures durability. Timely replacement of wear parts extends machine life. You can expect a 10 – 15-year operational lifespan with proper maintenance. Critical wear parts like dies and rollers may require replacement every 2 – 4 years under heavy use.

The best manufacturer offers reliable machines. Also, you should look for technical support and customisation. New Lehra provides proven briquette and pellet solutions across India. Machine selection depends on application and capacity needs.